WHAT DRIVES OUR DATA MONITORING & ANALYSIS

2CENSOR TECHNOLOGY

Learn how our sensors provide 24/7 monitoring of your mineral plant's assets.

ABRASIVE WEAR MONITORING SYSTEM

2Censor provides 360 degree visibility of all your plant's assets in real time.

Our dashboard digitizes plant operator intelligence based on inputs from assets such as pipelines and conveyors. The result provides you with actionable insights helping you to improve quality and reduce cost.

Data displayed to an operator can include Pipe Wear Indication, Chute Wear Indication, Bin Wear Indication, Battery Levels, Signal Strength, Sensor Loop indication, Location, Latitude, Longitude, Asset Numbers, Drawings, Isolation Points, Equipment Accessibility.

2Censor Components

Connecting the system together.

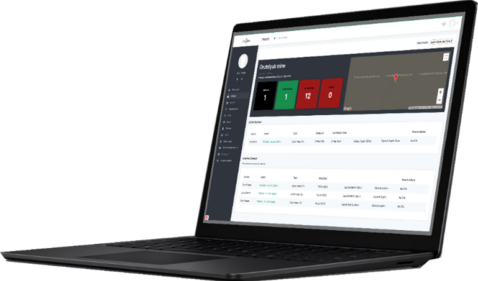

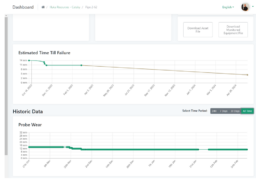

2Censor Dashboard

Our User Interface is used to display graphical information to operators and maintainers of plant and equipment.

The data is translated to display the current condition of the monitored asset. We use multiple algorithms to produce a forecast to failure date.

It is hosted securely using Enterprise Level cloud infrastructure.

Industrial 4G Wireless Gateway

A 4G capable Industrial Wireless Gateway is the bridge between the low power wireless network and the internet.

A single Gteway can cover a radius up to 5 kilometres (line of site) and is used to decrypt and collate Sensor Node data. The data is then uploaded to the 2Censor dashboard.

Alternatively this gateway can connect to your site network via an intermediary protocol converter that can convert the data to suit your network.

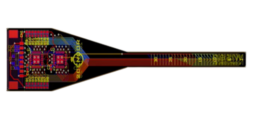

2C-Probe / 2C-Strip / 2C-Mill Sensor Probes

Sensor Probes are installed in assets at known points of failure. The 2C-Probe, 2C-Strip and 2C-Mill Probes can be made from multiple materials, shapes and lengths to suit the application.

Probes can be installed by penetrating the wear lining, or installed between the wear lining essentially becoming part of the liner, which then wears with the liner.

The sensor erodes with the asset and the individual data points are measured each millimetre, providing very specific wear data to the database.

Sensor Transmitter

The Sensor Transmitter uses the LoraWAN protocol to communicate wirelessly to the Gateway unit.

LORAWAN is a Low Power, Wide Area (LPWA) networking protocol designed to wirelessly connect battery operated 'things' to the internet in regional, national, or global networks.

Country specific radio frequencies are used to comply with the country’s regulatory authority.

Onboarding Application

To minimise human error, 2Censor have built a smart phone application (for Android and iOS) that uses near field communication (NFC) technology for onboarding Sensors onto site Assets.

Assets to be monitored are pre-loaded into the 2Censor Dashboard before the Sensors are deployed to site, data includes specific mine / site, and site location.

The application identifies serial numbers of each Transmitter by swiping over the transmitter to register the device.

This enables technicians from all around the world to easily assign the correct Sensor to the correct Asset without external assistance.

Data Ownership

We work with our customers requirements regarding data privacy and ownership if the data must remain on-premise.

We are able to supply the data to customers specific data management systems and also work with onsite IT teams to comply with their cyber security policies.