ABRASIVE WEAR MONITORING

2C-MILL

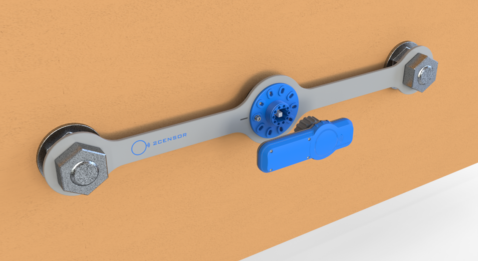

Patented Abrasive Wear Sensor designed to provide 24/7 condition monitoring of your mineral plant's assets.

The 2C-Mill Abrasive Wear Sensor is used in semi-autogenous grinding (SAG) / Ball Mill Liners.

Through collaboration with product engineers, we've successfully integrated our technology into SAG/Ball Mill Liners. This collaboration allows us to offer real-time condition monitoring and predictive maintenance for this crucial mining asset.

The significance of our contribution lies in mitigating the high costs associated with unplanned shutdowns resulting from liner failure.

By implementing our technology, we empower mining customers to conduct current condition monitoring even while the mill is in operation. Minimising the risks and consequences of unexpected failures.

This proactive approach enhances operational efficiency and reduces the potential financial impact on the mining operations.